The bottleneck comes down to physical constraints of our current system set up. We use a dual holding Kurt Vice, which is a very good vice as it provides over a ton of clamping pressure and can hold two pieces at a time. But in terms of practice in this day and age of ever higher competition... innovation is not only key, it is the only way to survive in this type of cut-throat business.

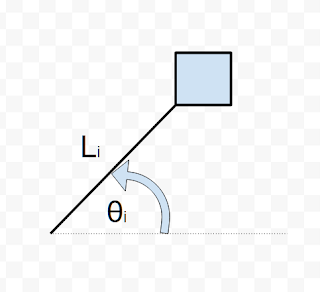

To increase productivity we were thinking of implementing a "Tombstone" which is a steel square prism which can rotate at precise angles and be held firmly. The advantage of using a tombstone in a 4th axis array is that you can load not only 4 tables with a very quick change between table, but you can also machine additional sides of the pieces that are tangential to the rotation of the tombstone thus reducing loading time significantly per part, and optimizing finished product within one running cycle.

I was considering using a pneumatic air cylinder which in essence is a 2 way piston which can thrust a rod forward or backwards in an airtight cylinder by redirecting air pressure.

The way the pneumatic piston works is by allowing air pressure to fill compartments on opposite ends of a sealed piston rod.

So I chose to model a relatively cheap pneumatic cylinder which has a large diameter bore to provide a lot of force with a small stroke length, since the jaws in essence don't normally have to open that wide to release the part. The length of the cylinder is also key to keep the vice compact, and able to fit neatly onto a tombstone array. I was also interested in a cylinder with pretty thick squared off stock, so that they can be machined and ground flat to ensure proper precision can still be held true.

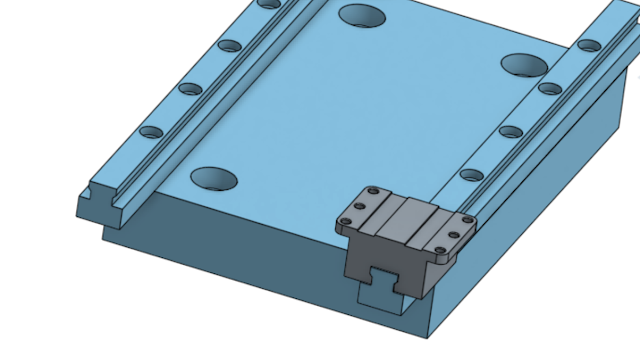

An adapter plate can then be bolted on top of the cylinder which would then allow the bolting of a precision linear rail.