I decided today to try and fix the casement window which is suppose to open a window through a means of cranking a handle. The problem is the actual assembly was missing and the only thing present was the rail on the side of the window.

A casement window is opened through a mechanism where a rigid arm pushes on the window through often some sort of wheel and track system through the rotating force of a lever and gears.

The generic window crank assembly wouldn't have been a quick install since the problem arose in the incompatibility of the wheel on the tip of the arm, and the rail system on the side of the window.

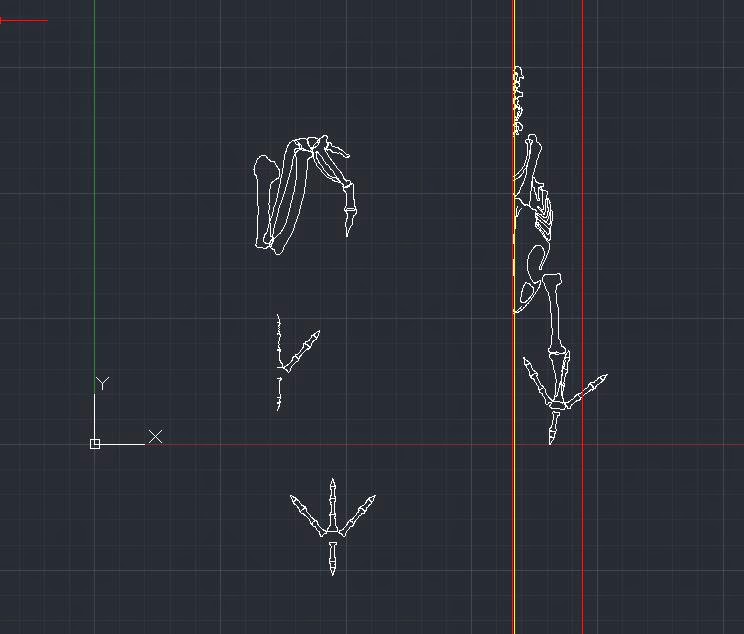

|

| This is the wheel on the tip of the arm that pushed on the window |

|

| This is the rail that was original to the window, notice that it has a groove to accommodate a wheel with a very specific cut notch so that the wheel slides snugly and cant slip off the track when sliding across |

The window was a bit old and the parts would have to ordered from the manufacturer if they were even in business any more. Nonetheless this would frustrate the typical homeowner, but this just brought me a rush of joy for a chance to solve a new problem.

There were essentially two ways to solve the problem, either you modify the wheel on the generic assembly, or you can make a custom rail to fit around the generic replacement found at your local hardware store.

|

| This is a quick sketch of the two possible solutions. Either modify the wheel, or make a custom rail |

I decided to choose the latter because removing that wheel and carving that notch via lathe on that plastic wheel wouldn't have been such a big deal. Even if I had to tap the metal housing to screw in the wheel again it still would have been less work than the rail. I chose to do the rail because, moving that window through simple friction involves a lot of force and friction, and I wasn't really at all confident as to the strength of that plastic wheel. The plastic wheel felt flimsy and I think it would have easily cracked and not withstand the loads once I removed that material and changed its shape.

I got a square block piece of aluminum stock and made sure that the inner square hole length was slightly large than the diameter of the plastic wheel.

I then measured the diameter of the shaft part of the wheel

|

| This measurement would be essential to making the sliding rail width that the wheel would slide on |

|

| Using that measurement I marked off where the rail would be cut on the aluminum square block |

Then came another engineering hurdle that I had to overcome, the issue of cutting the rail with only a jig saw, drill, and drill press at hand with simple tools. It was a tricky cut because I had to cut through one side of the square side but not the other.

My first attempt was to see if I could jerry rig something to make the jigsaw work because if I could make it work, it would save me time, and it would be much easier to make a smooth linear cut.

To solve this problem involved some sense of engineering and 2D thinking which I very much enjoyed. I drew out some of the problem solving instances I would need to think about prior to solving the problem and just made up some arbitrary parameters to define the problem.

The way the jigsaw works is, it plunges a blade up and down in a linear fashion through a specific length of stroke. I had to investigate to see if that length of stroke was within clearance distance to cut one side of the aluminum block and not the other.

|

| This is a quick sketch of the jig saw when looking at it head on (cutting blades facing you). I made up some arbitrary lengths that are of importance in this problem. Lo is the length when the jig saw is making the highest stroke into itself or the shortest length the blade relative to the supporting platform. "S" is the length of the stroke or the largest difference in length the blade makes when cutting. "delta" is some arbitrary length which is a factor of safety buffer distance we can risk later during practice. |

|

| This is the same situation now split into the two extremes of the stroke to better show what these arbitrary distances I came up with actually means. "C" is the overall clearance distance which includes the triangular point of the blade which is very important because it could still plunge into the metal and damage either the aluminum side or the blade itself. |

There are two possible scenarios that could result from this situation, one being beneficial to me, and the other forcing me to find another method. The first situation is that there exists a length that I could hold the jigsaw above the rectangular stock so that the clearance "C" is less than the inner side length "L" and therefore a single cut could be possible.

|

| The first beneficial scenario where the blade clearance length "C" is less than the length of the square block stock making possible a single cut through the stock block. |

|

| This is the second scenario where "C" is larger than "L" therefore cutting only one side of the aluminum stock block would not be possible and therefore we would be forced to find another way to cut the aluminum. |

After doing some measurements and a little bit of math, and some failed attempts just to make sure the math was right.. It was the second scenario so I was forced to find another way to make the cut.

Since it was already pretty late to try and rent out some tools or bother someone to finish the job, I had to resort to using the other tool I had at my disposal the drill press. The right tool would have been a dremel, or maybe a large aluminum bandsaw with some kind of jig, or maybe a cutting table with a fine metal cutting blade retrofit.

But alas I press on and start to find some drill bits which are slightly smaller than the overall width of the gap.

I started to drill holes as close to each other as I could with my cheap drill press and stay within the lines because I knew you could always remove material but can't add on.

|

| The larger the diameter of the drill, the less I would have to grind down on the sides, but then the holes would have to be dead center all the way down and not have a lot of room for error. |

|

| One of the benefits of having a X-Y vice is for these instances where you'd like to drill a series of holes all in a row. |

|

| Therefore to make the next series of holes, you would simply crank the handle and drill. |

|

| Before I knew it, I had a series of holes all cut within that small window tolerance of the width of the desired slot size |

|

| If you have the holes close enough together, you could easily break the aluminum between the holes with a simple set of needle nose pliers by just bending back until it breaks using the frame as the lever pivot point. |

|

| Making some quick work of this brute force slot cut through some crude methods. |

|

| This is how the bar looked like after the use of the pliers, no other refinement could be done without some kind of mechanism to make the parallel cuts. |

I decided to call it a night, and the following morning I managed to borrow a angle grinder to do some quick work of the rough edges of the drilled holes.

.JPG) |

| I clamped the angle grinder down and made sure it was secured in place |

.JPG) |

| I started to grind down the rough edges little by little getting closer to the marked edge to where it needed to be |

.JPG) |

| I also periodically sanded down the inside with a square file to ensure the smooth finish inside and out |

|

| To get closer to where the actual edge needs to be, I decided to file the edges to a smooth finish |

|

I inserted a metal bar on the floor of the aluminum car stock so I could file the sides away without scraping the floor of the aluminum block.

|

|

| Finally got the groove smooth enough to have the mechanism slide effortlessly |

|

| The final step involved drilling a few holes |

.JPG)

.JPG)

.JPG)